MAN eTGX for Long-Distance Haulage, MAN eTGS for Distribution

Electric mobility is no longer a distant dream; it’s becoming a reality in the world of commercial vehicles. MAN Truck & Bus has taken a significant step forward by launching the sale of its first heavy-duty electric truck, marking a pivotal moment in the push to decarbonize freight transport. With 600 order inquiries already in hand, the first 200 units are set to roll out to selected customers by 2024, paving the way for larger-scale production at MAN’s Munich plant starting in 2025. Let’s dive into the details of this exciting development.

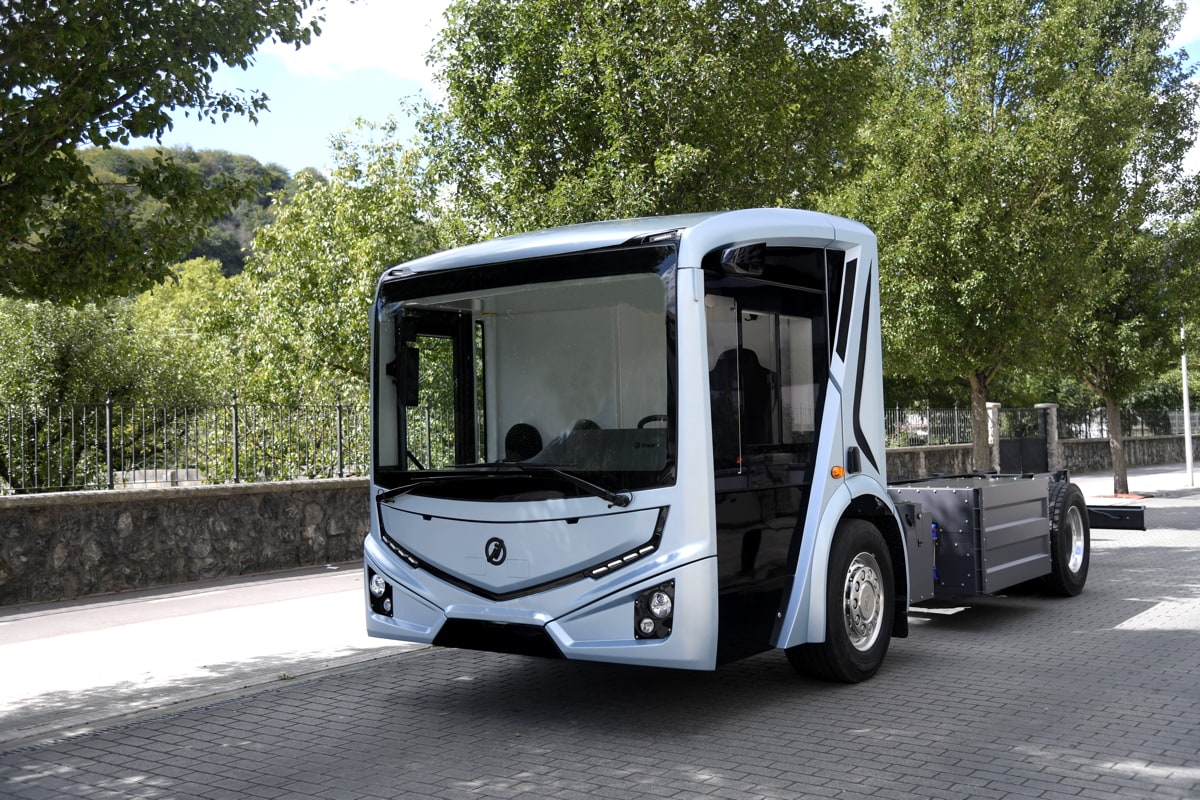

Driving Progress: MAN eTGX and MAN eTGS

MAN’s latest offerings in the electric truck segment include the MAN eTGX designed for long-distance transport and the MAN eTGS for distribution purposes. These vehicles boast impressive daily ranges of up to 800 kilometers, with plans to increase that to 1,000 kilometers in the near future. The key to their success lies in their high charging power, facilitated by two standards: MCS (750 kW) and CCS (375 kW), both featuring variable charging port positioning.

One notable aspect is the battery technology, specially developed by MAN for commercial vehicles and proudly labeled as “made in Germany.” To enhance flexibility and adaptability, these trucks come with three, four, five, or six modularly positionable battery packs. This modular battery concept allows for up to 2.4 tons of payload variance, depending on the specific transport task and range requirements.

For versatility, there are numerous semitrailer and chassis variants, including options with very short wheelbases (starting from 3,750 mm) to accommodate a wide range of trailer and body combinations. There’s even an ex-works volume tractor unit and chassis designed for transporting goods with up to three meters of internal height.

eMobility Consulting: Guiding the Way

Recognizing that a smooth transition to electric mobility requires more than just top-notch vehicles, MAN offers eMobility Consulting services that cover everything from fleet advice to charging infrastructure development. This includes crucial support for route analysis, cost optimization, and fleet management.

To make this transition even more seamless, digital tools like the MAN eReadyCheck and MAN eManager have been introduced. The eReadyCheck tool helps customers assess the feasibility of transitioning to electric-only delivery routes, while the eManager provides fleet managers with real-time information on the charging status of all trucks in their fleet.

Charging Infrastructure Expansion

Expanding the electric truck ecosystem beyond vehicles, MAN, in collaboration with the TRATON GROUP, Daimler Truck, and the Volvo Group, has launched a joint venture. The aim is to establish at least 1,700 high-performance charging points on or near highways and logistics hubs throughout Europe.

Moreover, MAN offers its own charging infrastructure solutions for customers, partnering with leading manufacturers like ABB, Heliox, and SBRS to provide a comprehensive charging network.

Modular Battery and Charging Connection Options

The MAN eTGX and MAN eTGS trucks are renowned for their flexibility when it comes to battery configurations. These trucks come with six battery packs, two located beneath the cab and up to four more positioned on the vehicle frame. This arrangement offers up to 480 kWh of usable battery capacity, enabling daily ranges of up to 800 kilometers.

The batteries are designed with NMC cell chemistry and a specially developed temperature management system. This combination provides a high energy density, compact design, extended service life, and rapid charging capability. With this setup, the optimal vehicle configuration can be tailored to suit various applications, from urban deliveries to regional transport and long-distance logistics.

For urban distribution tasks, where shorter daily ranges are common (up to 250 kilometers), recharging typically takes place overnight at logistics depots. In such cases, the modular battery concept allows for the use of fewer battery packs (three, four, or five instead of six), reducing the vehicle’s weight by up to 2.4 metric tons.

Optimal Positioning for Body Integration

The modular battery architecture is not only beneficial for battery configuration but also for the integration of body components. The flexible battery positioning creates additional space on the left or right side of the vehicle frame, ideal for high-performance pumps, equipment storage, crane outriggers, and other body-related components that require extra space.

Additionally, the standard placement of two batteries under the cab, similar to traditional combustion engine vehicles, ensures a favorable weight distribution. The central drive unit, which includes the synchronous electric motor, inverter, and a 2- or 4-speed transmission, is positioned centrally in the frame. This design enables a mechanical auxiliary drive to be easily incorporated to power body functions such as cooling units or hydraulic pumps, and it allows for a straightforward connection of an electromechanical auxiliary drive.

Enhanced Driving Experience: Comfort and Efficiency

Drivers of the MAN eTGX and MAN eTGS will find a comfortable and familiar environment inside the cabins. The driver-centric cockpit layout, coupled with a user-friendly interface, remains consistent with traditional MAN trucks. However, these electric trucks feature specific functionalities for electric vehicles, like recuperation settings, which also function as the continuous brake.

Recuperation can be controlled through the familiar steering column lever or a selectable One-Pedal-Driving mode. In this mode, recuperation intensity increases as the driver eases off the accelerator pedal, allowing for precise speed adjustments without using the brake. Simultaneously, it converts the vehicle’s kinetic energy into electricity, recharging the batteries.

Efficient energy management is essential for electric vehicles. The overall thermal management system intelligently utilizes excess heat generated during operation for cabin heating, reducing the need for additional battery energy. This ensures effective temperature control, even in winter conditions.

Furthermore, the cabin sizes available for these trucks align with the existing diesel series, offering options for both the MAN TGX and MAN TGS, each available in three roof height versions.

In conclusion, MAN’s introduction of the eTGX and eTGS electric trucks marks a significant leap forward in the commercial vehicle industry’s electrification journey. With these versatile, efficient, and environmentally friendly trucks, MAN is not just providing an alternative to diesel vehicles but also revolutionizing the way we think about long-haul and distribution transport. The transition to electric mobility is no longer a question of “if,” but “when,” and it appears the time is now.